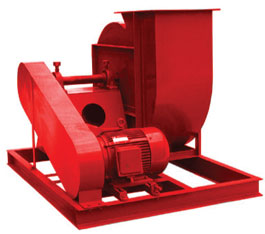

Volume Blowers

High Volume Blowers / Low Pressure Blowers:

These Blowers are used where application of Blower is based upon the volume of air moved.Shree Udyog provides high volume blowers that have volumetric displacement of air ranging from 1,000 to 10,000 m3/hr. and generate pressure from 10 to 200 mm wgp.Blowers supplied by us are manufactured using superior quality raw material. Our Impellers are statically and dynamically balanced to offer better performance. The materials of construction offered by us for these blowers are Mild steel (with protective coating and lining if needed / requested), Stainless Steel and Cast Iron.

Application:

|

General ventilation of fume |

|

Vapour exhaust |

|

Smoke exhaust |

|

Dust exhaust. |

|

Drying and cooling. |

|

Material Conveying |

|

|

Industries Catered:

|

Pharmaceutical Industries |

|

Chemical Industries |

|

Plastic / Polymer Industries |

|

Textile Industries |

|

Paper Mills |

|

Foods Processing Industry |

|

Printing, Packaging and Processing Industries |

|

Iron and Steel Plant |

|

Laboratories |

|

Refineries |

Range:

|

Air Flow (Volume) : 1,000 to 10,000 m3/hr. |

|

Pressure : 125 to 1,200 mm wgp. |

Centrifugal Blowers selection chart

| Pressure inches W.G. |

1" |

2" |

3" |

4" |

6" |

8" |

10" |

12" |

16" |

20" |

24" |

28" |

32" |

36" |

42" |

48" |

56" |

| MOTOR H.P. |

APPROXIMATE CAPACITIES IN CUBIC FEET PER MINUTE AT N.T.P. |

| 1/4 |

750 |

400 |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

| 1/2 |

1500 |

800 |

500 |

400 |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

... |

| 1 |

3000 |

1600 |

1000 |

800 |

675 |

300 |

250 |

225 |

150 |

|

|

|

|

|

|

|

|

| 2 |

6000 |

3200 |

2100 |

1600 |

1000 |

650 |

525 |

460 |

340 |

280 |

... |

... |

... |

... |

... |

... |

... |

| 3 |

8000 |

4800 |

3140 |

2400 |

1500 |

1080 |

1000 |

765 |

530 |

420 |

320 |

... |

... |

... |

... |

... |

... |

| 5 |

11500 |

7350 |

5150 |

4000 |

3000 |

1800 |

1600 |

1350 |

900 |

720 |

600 |

500 |

... |

... |

... |

... |

... |

| 7.5 |

14500 |

12000 |

7500 |

5500 |

4000 |

3000 |

2550 |

2000 |

1490 |

1080 |

300 |

850 |

720 |

... |

... |

... |

... |

| 10 |

20000 |

13400 |

9750 |

7750 |

5250 |

4000 |

3250 |

2900 |

2000 |

1575 |

1300 |

1175 |

1000 |

925 |

... |

... |

... |

| 12.5 |

27500 |

17000 |

12500 |

9750 |

6750 |

5100 |

4300 |

3575 |

2475 |

1970 |

1640 |

1400 |

1230 |

1150 |

900 |

... |

... |

| 15 |

33000 |

20000 |

15250 |

12000 |

8250 |

6250 |

5500 |

4300 |

3100 |

2370 |

2025 |

1700 |

1550 |

1400 |

1080 |

... |

... |

| 20 |

45000 |

20000 |

19500 |

15400 |

11000 |

7500 |

6800 |

5500 |

4320 |

3350 |

2700 |

2400 |

2100 |

1750 |

1440 |

1150 |

1000 |

| 25 |

70000 |

40000 |

25000 |

20000 |

12500 |

8750 |

8500 |

7200 |

5400 |

4250 |

3375 |

3000 |

2550 |

2325 |

1800 |

1250 |

1250 |

| 30 |

80000 |

50000 |

30000 |

25000 |

18000 |

10500 |

9500 |

8500 |

6500 |

5200 |

4050 |

3500 |

3175 |

2800 |

2250 |

1800 |

1500 |

| 40 |

100000 |

75000 |

45000 |

35000 |

23000 |

18000 |

11200 |

10500 |

7800 |

6500 |

5200 |

4400 |

3850 |

3300 |

2800 |

2250 |

1900 |

| 50 |

120000 |

80000 |

55000 |

40000 |

30000 |

22000 |

18000 |

12000 |

9500 |

8000 |

6750 |

5900 |

5250 |

4600 |

3700 |

3000 |

2450 |

| 60 |

140000 |

100000 |

75000 |

55000 |

38000 |

28000 |

22000 |

18000 |

11000 |

9300 |

7900 |

6600 |

6000 |

5250 |

4350 |

3250 |

... |

| 75 |

160000 |

132000 |

90000 |

65000 |

45000 |

34000 |

27000 |

22000 |

16000 |

10500 |

9000 |

7300 |

6250 |

5400 |

4675 |

... |

... |

| 100 |

180000 |

160000 |

120000 |

85000 |

60000 |

46000 |

37000 |

28000 |

25000 |

18000 |

15000 |

12000 |

11000 |

10000 |

8000 |

... |

... |

| 120 |

200000 |

180000 |

140000 |

110000 |

70000 |

55000 |

45000 |

30000 |

30000 |

24000 |

20000 |

15000 |

13000 |

11500 |

9000 |

... |

... |

| 150 |

262000 |

230000 |

160000 |

120000 |

80000 |

60000 |

52000 |

40000 |

35000 |

30000 |

25000 |

20000 |

15000 |

12500 |

11000 |

... |

... |

|

|

| |

|

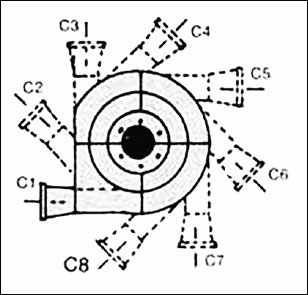

Clockwie direction of roatition

(Viewed fron sucction end) |

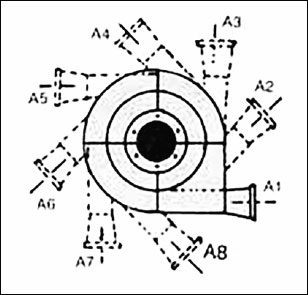

Anti-Clockwie direction of roatition

(Viewed fron sucction end) |

How to order:

When sending an enquiry kindly specify the following:

|

Volume of air to be displaced (units: m3/hr. | c.f.m.) |

|

Total static pressure. Please specify pressure to be considered at working conditions or NTP. (units: mm of wgp | inches of wgp | mm of Hg | inches of Hg) |

|

Temperature or humidity conditions. |

|

Direction of rotation from while viewing from suction end. |

|

Direction / Position of discharge. (refer direction image, Incase the direction/position is not specified we will supply the fan with clockwise direction of rotation and C1 discharge position.) |

|

Cross section of discharge (round | Square | rectangular) |

Spares Offered

|

|

|

| Inspection Door |

Drain Plug |

Filter |

| |

|

|

|

|

|

| Impeller |

Silencer |

Suction & Discharge guard |

|